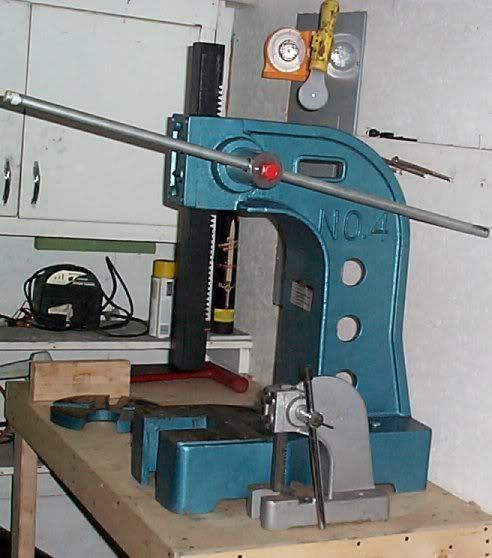

It's something I have been coveting for some time and I look forward to being able to press stuff instead of ramming. However I feel the need already to modify it somewhat.

The problem is that the maximum height of the workpiece is 8.5 inches [215mm actually]. Ideally I would like to be able to press a 1lb rocket with it, which would require at least 15 inches of height. [7.5 inches for the tube, and 7.5 inches for the drift]

The circular anvil is removeable so my initial thoughts are to take it off and somehow clamp an anvil [bit of I-beam mebbe?] underneath it. Whilst there are two holes at the back of the press, there are no holes at the front where mounting would be required.

Has anybody got any advice on drilling cast iron, or any thoughts on a more elegant solution? All advice gratefully received....