Ball Mills

#481

Posted 10 January 2007 - 04:51 PM

This can be alleviated in several ways. One is to pre-dry the substances being milled. Not an option if you subscribe to the "add water to your black powder to avoid sparking" idea.

Another is to add a "bump" to the milling operation. Depending on your mill, this can be accomplished by adding an eccentric to either the jar or to the roller that drives the jar.

If adding to the jar, it should be done in more than one place to avoid repeated "bumps" in exactly the same place in the jar's rotation.

#482

Posted 10 January 2007 - 05:44 PM

For a number of reasons I prefer damp milling BP with 3 - 4 % of water / IPA mix . The comp does start to compact and stick to the jar after 90 minutes or so, but with a thinish jar you can just pick it up and squash it a bit to make the caked comp crumble, shake it and put it back on the mill... repeat every 90 mins until your milling is done...As to the milled compound sticking to the walls of the jar, even with just a few percent moisture content, once milling begins and the compound is compacted- sticking can occur.

Edited by BrightStar, 10 January 2007 - 05:45 PM.

#483

Posted 10 January 2007 - 07:22 PM

#484

Posted 11 January 2007 - 07:50 AM

The media volume would then be 4 litres - thats big but also effective!

MfG

newtoolsmith

#485

Posted 11 January 2007 - 10:41 AM

BTW anyone out there know enough about electronics to tell me how to work out the power requirements of the motor so I can search for a suitable power suply? 3 hours with a 1 hour down time is boring to have to keep remembering on and off times?

I also use a 12v dc motor for my mill

I use the 1.3L jar from inoxia with 1kg of media

The power requirement for this motor is just above 4.6v dc ( below this the motor will stall)

I have achieved this by using a fixed resistor of 1 Ohm. and a further Variable resistor of 1 Ohm Max

Running at 1.75 ohms resistance, the mill seems to turn the mill at a reasonably slow speed. I do not experience too much trouble with clumping.

I guess, If you can find a 6v dc power supply, Very little extra resistance would be needed

Motor cycle battery charger seems to spring to mind

#486

Posted 12 January 2007 - 01:12 PM

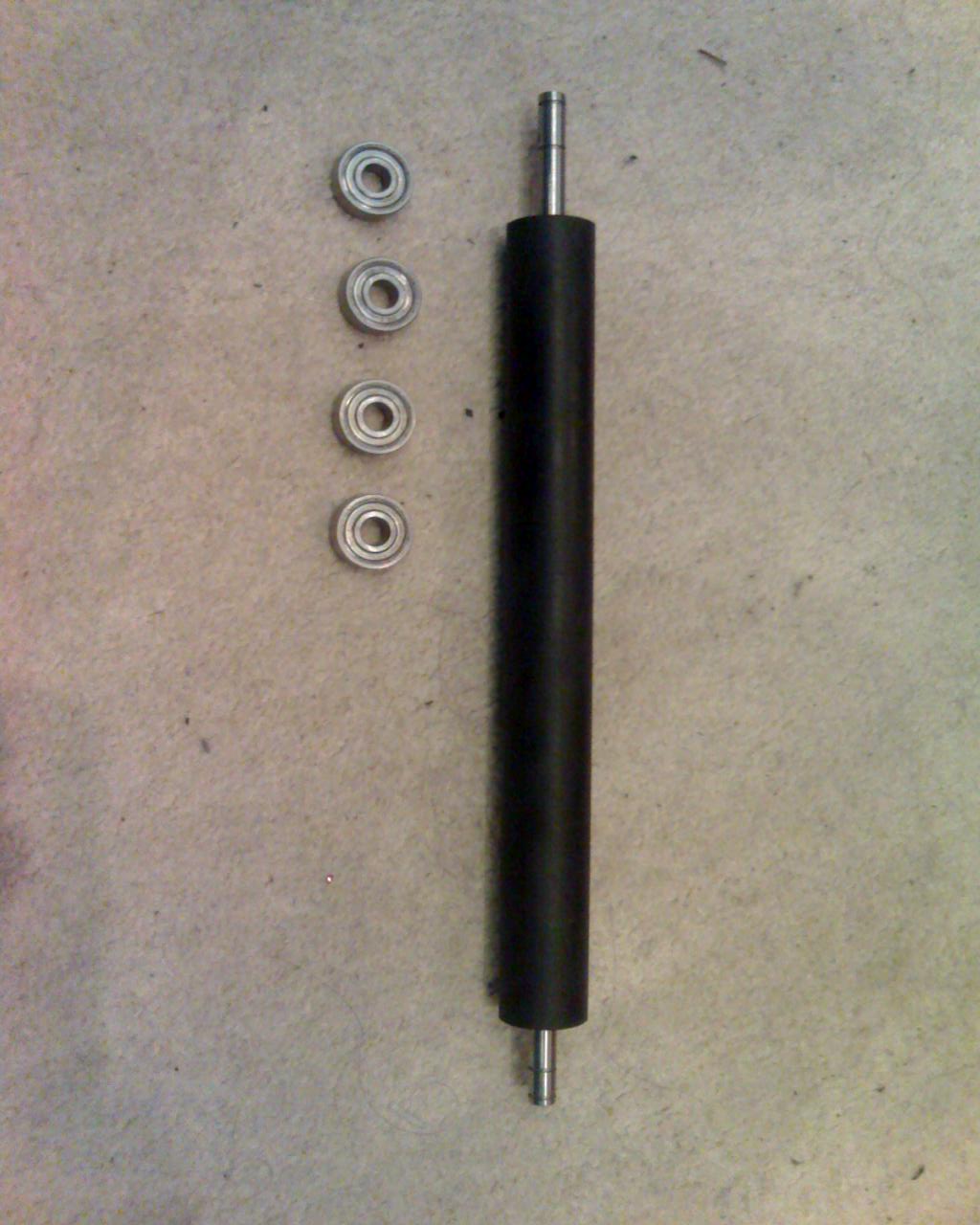

They are stainless steel rodded centres with rubber outers measurements are as follows:

total length 300mm

rubber roller length 235mm

rod sticking out at the ends is eccentric 26mm at one end and 39mm at the other end and 8mm diameter.

the rubber part is 25mm diameter.

They are all brand new and I would like a £9 for a pair including postage?

I have a set of 4 bearings for them too but I bought these so Ill want £16 for them not inc postage (ill include it if you are buying rollers too)

If anyone wants them please PM me and we can sort it out

Phill

Click here for Cooperman435, THE online shop for chemicals, materials and tooling

Click here to email me Personally,

Click here to email Optimum Fireworks, West Yorkshire's premium Display Company

#487

Posted 14 January 2007 - 10:19 PM

Say hi if your interested Ive already been asked about 1 pair

Click here for Cooperman435, THE online shop for chemicals, materials and tooling

Click here to email me Personally,

Click here to email Optimum Fireworks, West Yorkshire's premium Display Company

#488

Posted 16 January 2007 - 06:57 PM

Many thanks.

#489

Posted 16 January 2007 - 08:28 PM

Just a quick question on ball mill construction. What is the optimum position for the shafts in relation to the jar? If we assume that the jar has a 6inch OD would it be better to have the shafts at about 2inch seperation rather than 3 or 4 inch, therby ensuring the shafts are at 7 and 5 oclock where 6 o clock is directly under the jar?

Many thanks.

If the rods are going to be BOTH driven by the motor then the wider they are apart the better (within reason) so that would be 4 and 8 o'clock If you only intend to have one shaft driven then closer is better so 5.15 and 6.45 o'clock.

THis will give the best grip on the jar

Click here for Cooperman435, THE online shop for chemicals, materials and tooling

Click here to email me Personally,

Click here to email Optimum Fireworks, West Yorkshire's premium Display Company

#490

Posted 16 January 2007 - 09:59 PM

#491

Posted 16 January 2007 - 10:16 PM

#492

Posted 19 January 2007 - 02:55 AM

#493

Posted 17 February 2007 - 08:23 PM

Would vigirously washing out the jar with an appropriate solvent be enough or should I just leave it.

#494

Posted 18 February 2007 - 11:09 PM

#495

Posted 19 February 2007 - 12:30 PM

What washing program would be appropriate for BP?I was joking, however I suppose an old wahing machine could be modified, although that sort of capacity would probably be unecessary

Wouldn't a full cotton program followed by 1100 spin tend to cause sticking to the drum?

I'd start at wool and work up to synthetics with a 500 spin.

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users